You may be asking yourself, “What is a rewinding electric motor?” If so, you have come to the right place. Rewinding electric motors are characterized by their absence of a rotating magnetic field. These motors also minimize copper losses and air pockets while improving efficiency. In this article, we’ll take a closer look at these motors. Read on to learn more about rewinding electric motors and how they improve efficiency.

They Have No Rotating Magnetic Field

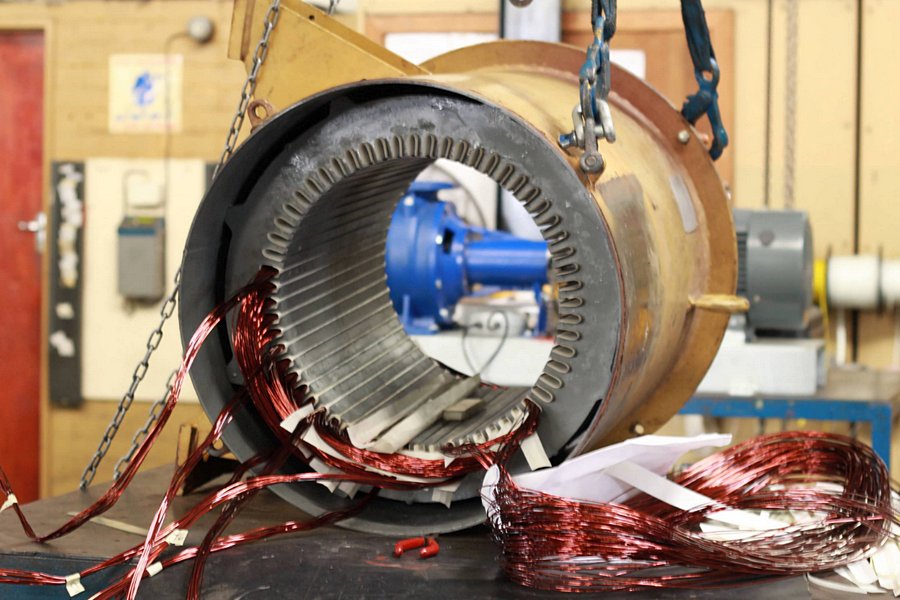

Rewinding electric motors are based on the principle of a fixed magnetic flux created by three-phase windings in a stator. The stator windings are connected in a delta or star configuration. This configuration causes the rotor to slip behind the field, allowing it to turn. This is how voltage and current are induced. A three-phase DC motor has three phases: a stationary part called the stator and two rotating parts, a commutator and brushes. These components are connected together via a magnetic flux induced in the rotor.

Reduced Air Pockets

By reducing air pockets, rewinding electric motors can improve their efficiency and life. Increased winding wire area reduces air pockets and heat transfer. This method also reduces copper losses. Minor mechanical repairs may be required during rewinding. Replacement bearings should be identical to those supplied by the manufacturer. However, proper installation is essential to avoid bearing failure.

They Minimize Copper Losses

Rewinding electric motors can improve overall efficiency by increasing the amount of copper that is applied to the windings. Depending on the size and type of rotor, the amount of copper can be increased by up to 10% by increasing the area of the copper wires in the rotors. This method is used to minimize copper losses due to winding imperfections. In addition to increasing the copper area, rewinding reduces the rotor loss due to corrosion.

They Improve Efficiency

The benefits of rewinding electric motors are multiple. The increased surface area of the winding wire reduces resistive losses and reduces heating, resulting in greater efficiency. The wire is also more tightly wound, allowing less movement, extending the mechanical and fatigue life of the winding. By using this process, 90% of all electric motors can improve their efficiency. Read on to learn about its benefits.

They Extend Life

Rewinding electric motors can help them last much longer. The process can reduce running costs, maintenance schedules, and electric motor maintenance, thereby improving overall facility efficiency and profitability. However, it’s not enough to just rewind an electric motor. It’s also crucial to protect its insulation. Visit Ghaima Group to learn more about it.

Skateboarder, father of 3, fender owner, International Swiss style practitioner and growthhacker. Doing at the intersection of simplicity and function to create great work for living breathing human beings. Concept is the foundation of everything else.